Rethinking

Biomanufacturing

TECH CALL FOR NOVO NORDISK

To form collaborative and game-changing alliances in biomanufacturing

Novo Nordisk is searching for new technology to help us change the game in aseptic biotech manufacturing. In today’s rapidly evolving biotech landscape, it’s imperative to address the increasing complexity of keeping productivity high while managing a high mix of new products. Novo Nordisk manufacture low volume, high mix AT-SCALE across a global manufacturing network and we believe that collaboration is key to successfully turning ideas into reality.

Novo Nordisk is committed to building strategic partnerships and strong co-creation alliances to develop technology that deliver tangible value for all involved parties. Apply now and join us in shaping the future of biotech- and pharmaceutical manufacturing. The application deadline is 1 November 2024.

Who can apply?

Solutions must be within the Technology Readiness Levels (TRL) range of 5-9. While Nordic markets are preferred, global solutions are welcome. The Tech Calls are open to SMEs, startups, and spin-outs across pharma, biotech, water, food, data science, space, environment, and robotics.

CHALLENGE #1

Fast process validation solutions

to improve and simplify critical process steps

CHALLENGE #2

FAST QC-ELEMENT SOLUTIONS

TO MINIMIZE OFF-LINE CONTROLS

CHALLENGE #3

Pioneering Wash and sterilization

To rethink cleaning and sterilization processes of equipment

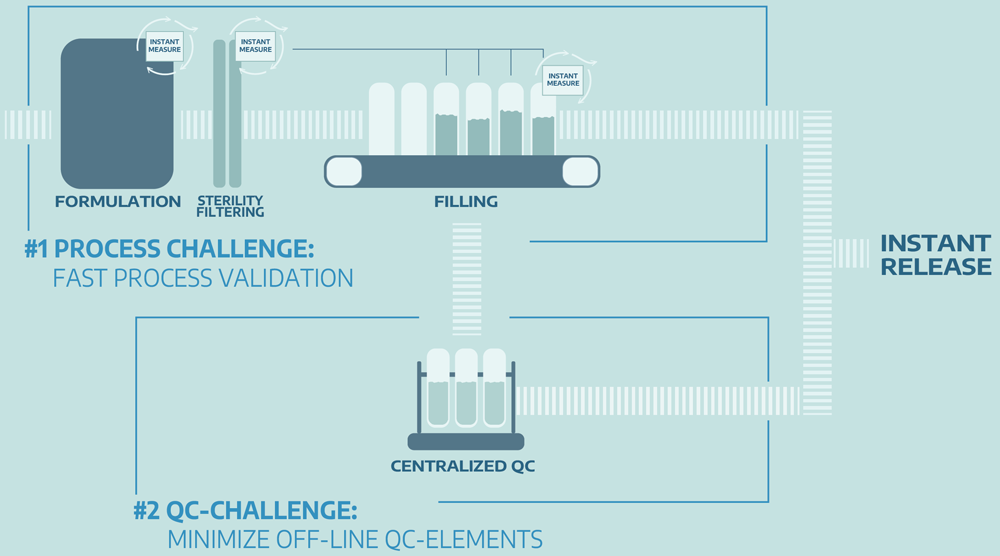

Challenge #1

FAST PROCESS VALIDATION SOLUTIONS

TO IMPROVE AND SIMPLIFY CRITICAL PROCESS STEPS

Novo Nordisk is seeking innovative in-on-at line process control solutions to optimize the efficiency of manufacturing processes, to accelerate production timelines and to minimize risk of lost products in small volume aseptic production. Solutions should enable fast decisions, process validation, preferably enhance real-time monitoring and limit the need for take-out samples.

Novo Nordisk hopes to build more efficient production lines, effectuate decision-making and simplify critical process steps for product-solution measurements to prepare aseptic manufacturing for the future. Help solving their biomanufacturing process challenge with your solution.

- How is it possible to get instant feedback in-on-at line?

- How can we reduce sample sizes, and avoid scrapping of sample materials?

- Which methods do we have available to measure for process- and product attributes? Such as leachables, bioburden, protein conditions, or the like.

Challenge #2

FAST QC-ELEMENT SOLUTIONS

TO MINIMIZE OFF-LINE CONTROLS

Novo Nordisk is seeking cutting-edge solutions to reduce the need for traditional centralized quality controls off the line in aseptic production. To enable efficient release of small volume medications for timely patient access, solutions should offer ways of reducing the off-line QC-elements, preferably propose smart integration in-on-at the aseptic production line.

Novo Nordisk aims to find fast QC-element solutions that can minimize off-line controls, thus offering solutions for fast in-on-at line measures. Help solve the QC-challenge with your technology.

- How can we move quality control closer to the production?

- How can we apply sensor inputs as improvement tools?

- Which new analytic methods can be put to use and measure in higher pace

- Which kind of quality indication tests can provide early-stage indications of quality control?

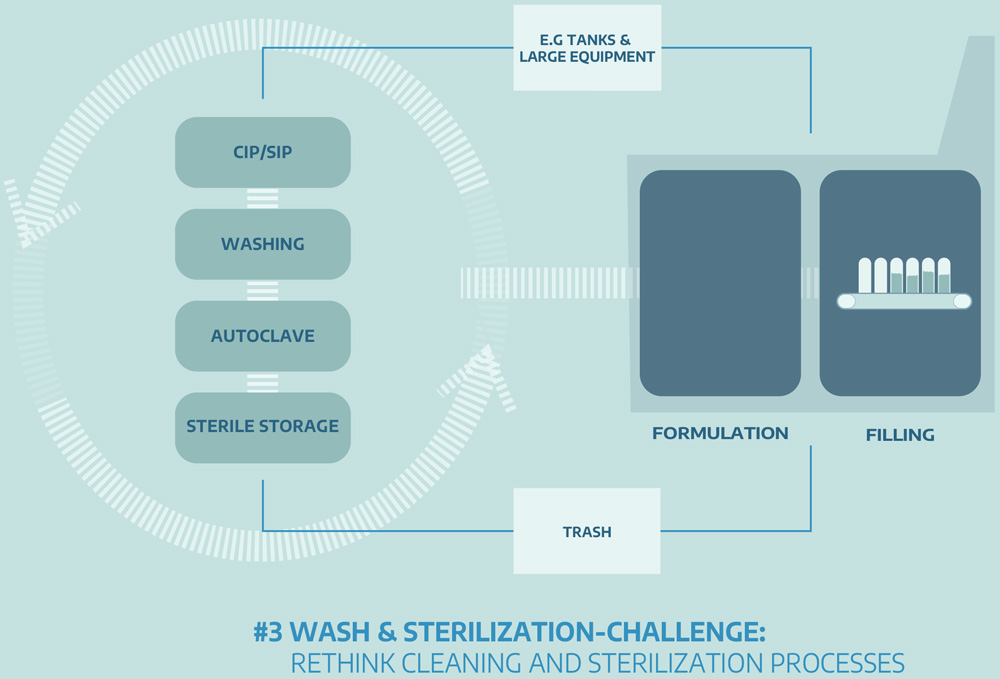

Challenge #3

Pioneering Wash and sterilization

To rethink cleaning and sterilization processes of equipment

Novo Nordisk is searching for radically innovative solutions to reduce or eliminate the need for traditional washing, decontamination, and sterilization processes in the biotech production sphere.

In today’s pharma industry, washing machines are ‘big, bad, and inefficient.’ Novo Nordisk is eager to find solutions that eliminate ‘Wash & Sterilization’ completely or significantly reduce processes and/or time. Help us solve this challenge by answering:

- How can we prove that equipment is not contaminated to eliminate ‘Wash & Sterilization’ ?

- How can technologies help significantly speed up the process?

- How can washing, decontamination and sterilization processes be done quickly in-line/at place, rather than in a separate facility?

NIRAS GREEN TECH HUB

NIRAS Green Tech Hub is facilitating the search for new innovations, partnering with Novo Nordisk, who are committed to solve essential challenges in their aseptic production through collaborative testing of new technologies. NIRAS Green Tech Hub provides support and for the new strategic partnerships and alliances to emerge. As Novo Nordisk’ innovation partner we endorse strong matches, we add potentially needed engineering competencies, and uphold momentum and progression during the joint collaboration. Together, we aim to develop technologies that deliver tangible value for all involved parties for the future of biomanufacturing.

If you have any questions, please feel free to contact us at:

Stine Sivertsen

+45 22 40 70 41

STMS@NIRAS.DK

Sophie Bech

+45 28 14 20 44

SBEC@NIRAS.DK

About Novo Nordisk

Novo Nordisk is a leading global healthcare company, founded in 1923 and headquartered in Denmark. Their purpose is to drive change to defeat serious chronic diseases. They do so by pioneering scientific break- throughs, expanding access to their medicines, and working to prevent and ultimately cure disease. Novo Nordisk employs about 63,400 people in 80 countries and markets its products in around 170 countries.